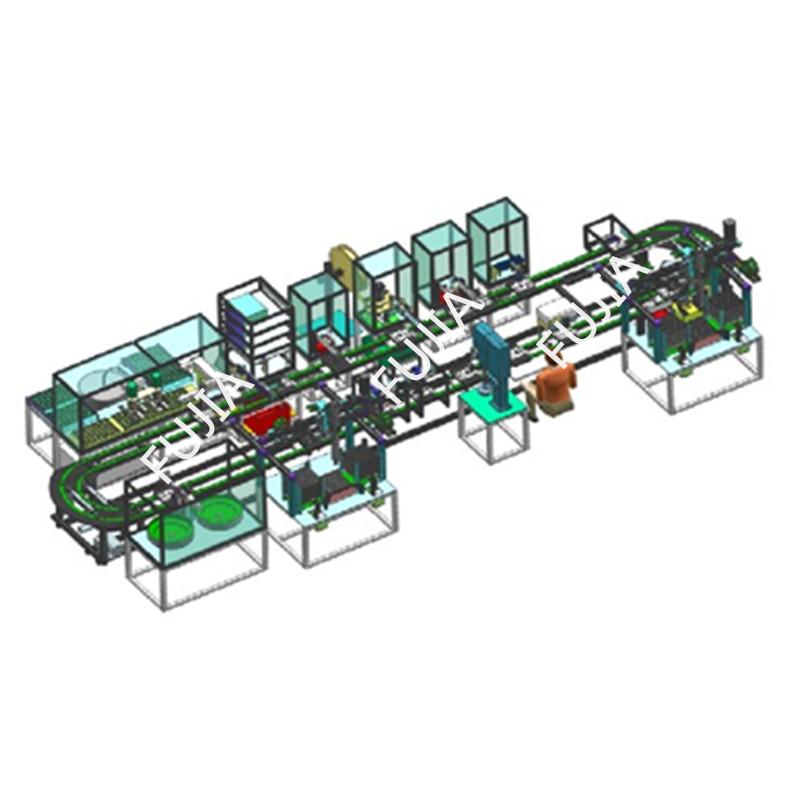

Theory

In a non-contact manner , a focused infrared beam transmits heat energy to the targeter weld area. Under the action of infrared energy, the plastic surface is rapidly heated and plasticized. After the temperature reaches the welding requirements, the cylinder or servo motor will push the plastic welding surface to generate certain pressure, which then allowed to re-solidify and weld the two components tightly.

Advantage

Energy-saving and enviroment friendly, no contamination

Fast heat up speed and accurate tempreture control(+/-1°C)

Non-contact heat input welding with high tempreture permeability

High pulling strength, clean welding area, no flash,no lose particle,no damage to the product to the product

Low maintenance cost,extra long infrared radiator life time(up to around 20K-60K hrs)

Ideal for most common thermoplastics materials, especially poly-carbomate(PC),polyacetal(POM),Polyamid(Nylon,PA),Polypropylene(PP).

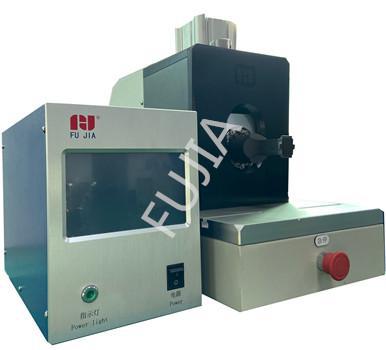

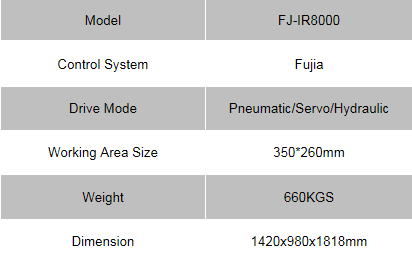

Parameter

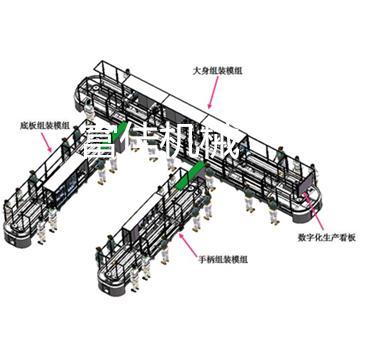

Fujia,an intelligent equipment manufacturer, As a company we provide integrate designs, production,sales and service and have gained several patents and national hi-tech enterprise certificates. With advanced technology,excellent quality and professional after-sales service ,we're highly recognized by the global top 500 companies and have their continuous cooperation.

Address: No. 48, Hongfeng Road, Chang'an , Dongguan , Guangdong

Tel: +86 0769-85330433

Email: [email protected]

Fax: 0769-81766269